It is mostly caused by the growing demands of thermo-hygrometric control of building envelopes that are increasingly stagnant. This is a very important problem that is often neglected during the design phase.

The D.P.C.M. del 5.12.97, " Passive acoustic building requirements", provides for heating systems not to exceed 35 dB in residential areas (A) for intermittent services (lifts, bathrooms, plumbing drains, faucets, toilets) and 25 dB (A) for services at continuous operation (heating, air conditioning, ventilation).

If you are a customer of a hotel as you may have been able to find out personally, not always the location of the hotel is indicative of silence or noise; you can find a hotel located above a pub and still enjoy almost total silence, or sleep in rooms in the middle of the woods and perceive constant noises, often coming from within the same facilities (thermal power stations and climate control, laundries, air

conditioning, kitchens, rooms small isolated from each other ...).

The nightmare of every traveler is to sleep in a noisy room due to:

✔ Partitions between neighbouring premises for example rooms/bathrooms not properly insulated. Walls must provide a good level of airborne sound insulation by preventing noise from passing from a boundary partition to adjacent space.

✔ Vibrational noise of trampling and dragging furniture toward the underlying premises on the floors/ceilings.

✔ Noise caused by heating (thermal power stations) and climate control.

If you run a Hotel you can ask for advice from 2B Resine engineers who will measure the noise level within your facility after a design description and according to current regulations.

With our soundproofing, your customers will be able to sleep peacefully! Our company operates in the field of environmental acoustics and aims to identify the most suitable products for each project and proposes aesthetical solutions post operam

The most important plant categories from the point of view of the acoustic emissions on which 2B Resine works are as follows:

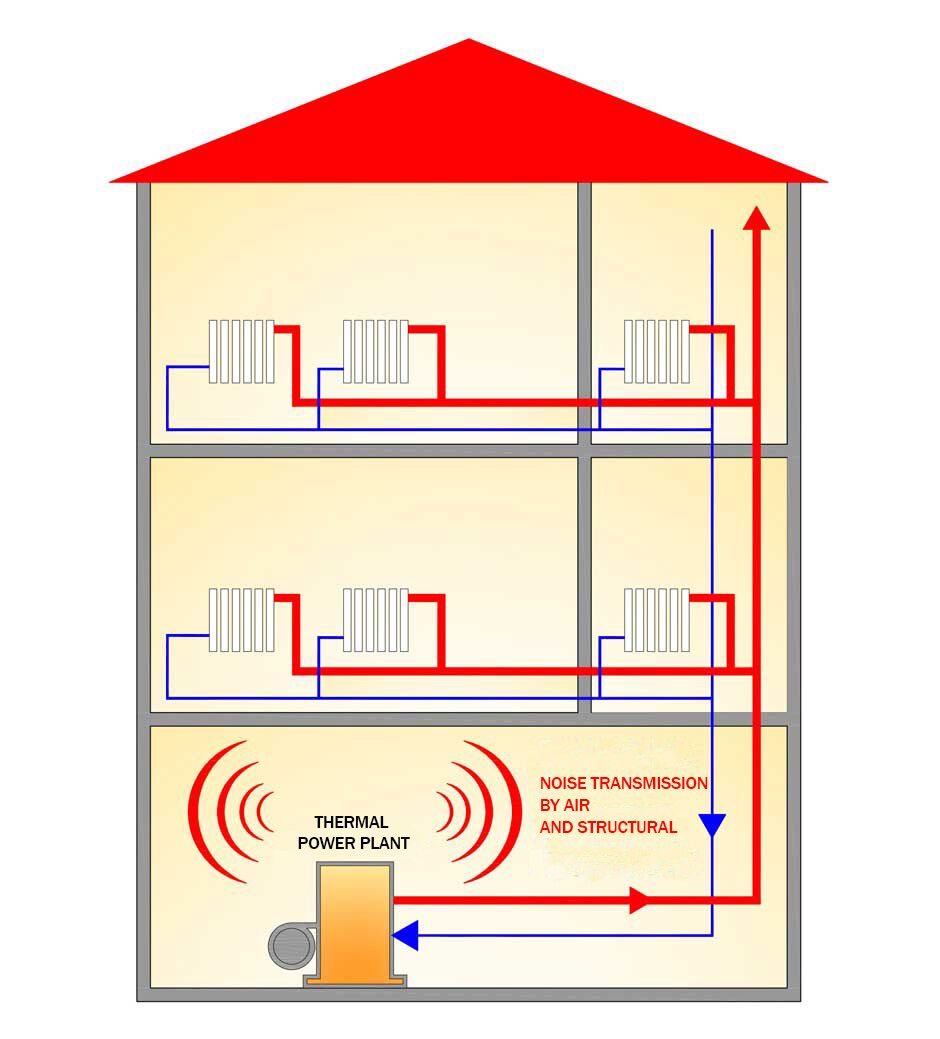

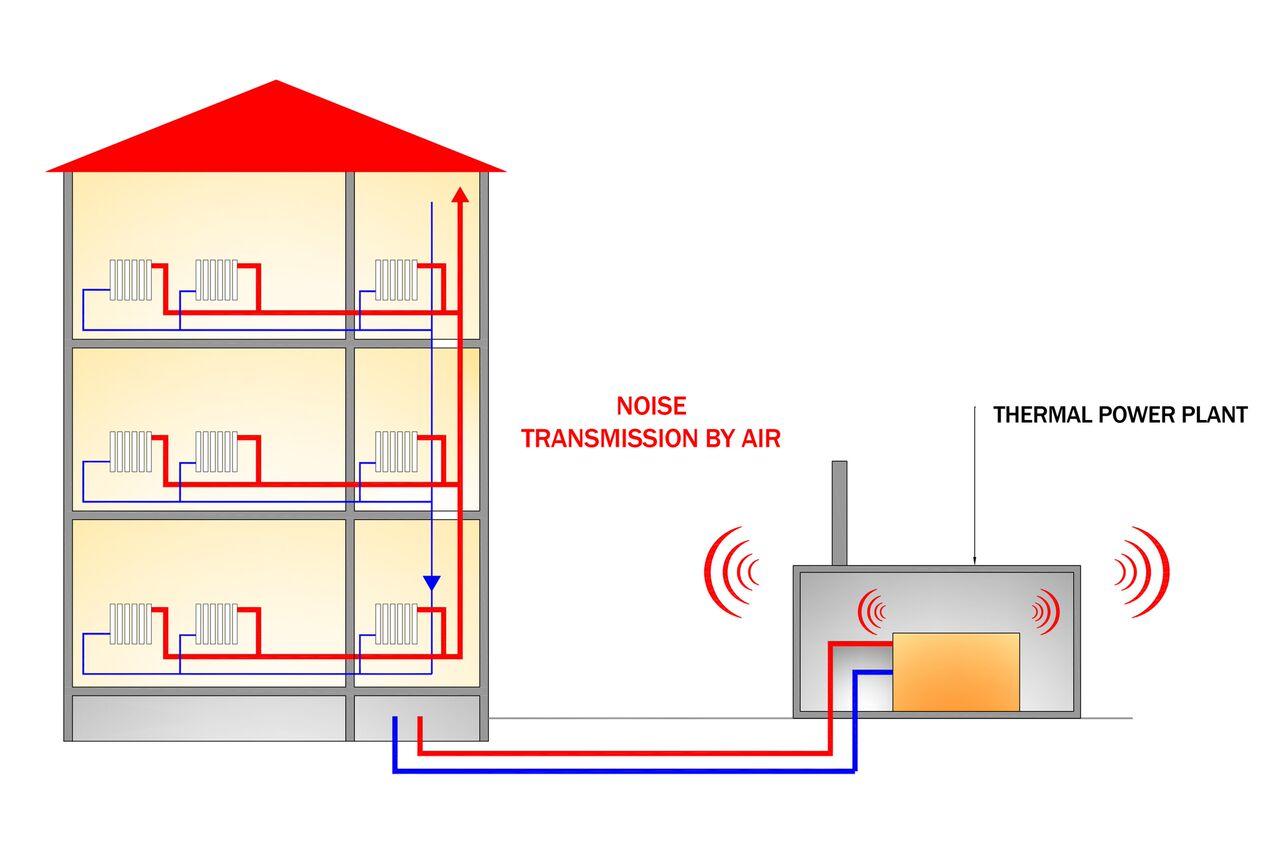

Usually heat production occurs by means of heat generators usually installed in a closed place called thermal power plant . Cold production also takes place by means of machines, parts of which are installed inside, and some outside. 2B Resine addresses the possible technical solutions to be applied ranging from machine noise reduction to vibration and sound insulation along the propagation path. 2B Resine pays attention to their positioning , to the location and eventual soundproofing of the air vents, to any noise emissions from chimneys, to vibration and solid sound transmission through the bases on which boilers, chillers, pumps , etc. rest. The noisy components of thermal power plants are: boilers, pumps, pipes.

2B Resine first examines the environment in which the machines are installed, which is the technology center (sound propagation under confinement, acoustic absorption and reverberation time, cumulative effects from different machines installed in the same place, etc.);

Secondly, it studies the transmission of noise to the outside, through masonry and doors (sound insulation) or through the necessary openings (ventilation grilles, external air intake and expulsion , chimneys, etc.);

Finally, it studies the free sound field transmission from the technology center, intended as a source of noise, to the potential receptors (presence of reflecting surfaces, acoustic barriers, etc.).

2B Resine acts on vertical and horizontal wall structures to ensure high noise absorption in the local source, associated with low transmission to surrounding environments that are subject to potential disturbance.

Air conditioning and ventilation systems of all sizes are increasingly becoming a source of noise and disruption. Air treatment units (UTAs) draw air from the outside environment and treat it according to the indoor climate requirements, using channeled systems for air distribution in the building: they vary the temperature, humidity, purity, etc. Or the air can be aspirated from the indoor environment (for example to cool during the summer) and expelled in the outside environment.

UTAs have various sources of disturbance:

✔ The noise emitted by the machine through the air intake and expulsion channels (propagating towards the interior of the building through the same channels).

✔ The noise emitted by the machine in the surrounding environment and in the nearby rooms.

✔ Vibrations transmitted by the machine to the host structure.

2B Resine manufactures soundproofing of air conditioning and ventilation systems; it uses SOUNDPROOF MATERIALS with high sound insulation for full or partial coverage of the sound source and SOUND ABSORBING materials for the possible inner lining of ducts.

To overcome the excessive noise of conditioning machines, heat pumps and air handling units, the 2B Resin products are particularly suitable for their high acoustic performances in addition to their adaptability to any situation. Noise sources are represented by the intake and expulsion fans of the air treatment units. These technical premises are subject to similar considerations as those for thermo-refrigeration plants; care must also be paid to sound-proofing of air distribution ducts.